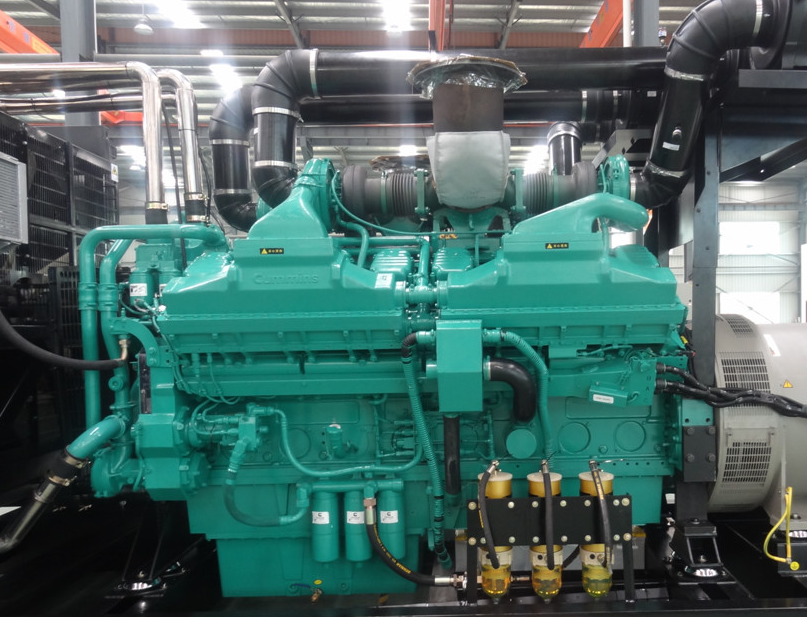

Cummins diesel generator sets are widely used in the field of backup power supply and main power station, with a wide range of power coverage, stable performance, advanced technology, and a global service system.

Generally speaking, Cummins generator set gen-set vibration is caused by unbalanced rotating parts, electromagnetic aspects or mechanical failures.

The unbalance of the rotating part is mainly caused by the unbalance of the rotor, coupler, coupling and transmission wheel (brake wheel). The solution is to find the rotor balance first. If there are large transmission wheels, brake wheels, couplers, and couplings, they should be separated from the rotor to find a good balance. Then there is the mechanical loosening of the rotating part. For example, the looseness of the iron core bracket, the failure of the oblique key and the pin, and the loose binding of the rotor will cause the unbalance of the rotating part.

The failure of the electrical part is caused by the electromagnetic aspect, which mainly include: short circuit of rotor winding of wound asynchronous motor, wrong wiring of AC motor stator, short circuit between turns of excitation winding of synchronous generator, wrong connection of excitation coil of synchronous motor, broken rotor bar of cage type asynchronous motor, stator and rotor air caused by deformation of rotor core. The gap is uneven, causing the air gap magnetic flux to be unbalanced and causing vibration.

The main faults of the vibration machinery part of the Cummins generator set are: 1. The shaft system of the linkage part is not aligned, and the center lines are not coincident, and the centering is incorrect. 2. The gears and couplings connected to the motor are faulty. 3. Defects in the structure of the motor itself and installation problems. 4. Load conduction vibration driven by the motor.

Post time: Mar-07-2022